Finger Washers

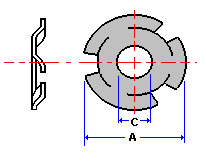

Finger washers combine the flexibility of curved washers and the distributed loading points of wave washers. They are adaptable to a space with large inside and small outside diameter. Length of fingers as well as their number and thickness may be varied to obtain a wide range of characteristics. Load, deflection and stress are approximated by assuming that the fingers are cantilever springs; then Associated Spring’s engineers the samples and tests to prove the design.

This family of washers can be broadened to include an infinite number of stars, and other shapes. Finger washers are used in static applications such as applying an axial load to ball bearing races to reduce vibration and noise, not recommended for fatigue applications.

Our broad experience with metal stamping enables Associated Spring to offer the exact custom finger washer to meet your application requirements. Belleville, Slotted, Wave, Curved and Disc spring washers are also available in many materials and sizes. Our plants are third-party certified to AS9100, ISO9001 or TS16949 and ISO 14001 depending on the markets serviced.

How to Specify:

A blueprint or sketch is the best way to specify your custom finger washer. Consultation with Associated Spring engineers early in the design stage will ensure all critical aspects of your spring washer will be met. Associated Spring engineers can develop a print if provided with the space available and part requirements, heights, loads, etc.

Instead of < and > please use “less than” or “greater than”; instead of / use “-” or “;” to separate values