Spring Washers Overview

Spring washers, also called disc and wave springs, exert an axial force in limited spaces. The force applied can be very light to high depending on the design chosen and space available.

The custom spring washers manufactured by Associated Spring can exert a thrust load and absorb vibration, reduce end play or apply pressure. The state of stress is primarily bending, and most of the general design considerations for flat springs apply. Spring washers are used in seals, bearings, motors and other rotating mechanisms, and are a popular option because of the need for compactness.

Associated Spring has broad experience with metal stamping enables us to offer the exact custom spring washer or metal stamping product or service to meet your application requirements. Belleville, Slotted, Curved, Wave, Finger and Disc spring washers are available in many materials and sizes. Our plants supply washers that are AS9100, ISO9001 or TS16949 and ISO 14001 certified depending on the markets serviced.

If you’d like more information on Belleville, wave, spring, or transmission washers, please contact our engineered parts experts.

How to Specify:

A blueprint or sketch is the best way to specify your custom spring washer. Consultation with Associated Spring engineers early in the design stage will ensure all critical aspects of your component will be met. Associated Spring engineers can develop a print if provided with the space available and part requirements, heights, loads, etc.

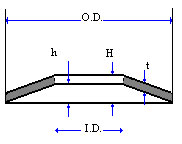

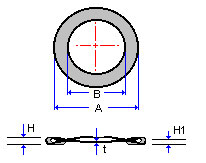

Belleville Washers

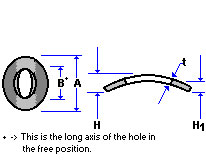

Curved Washers

Wave Washers

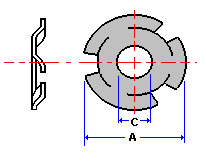

Finger Washers

Instead of < and > please use “less than” or “greater than”; instead of / use “-” or “;” to separate values