Belleville Washers

Belleville washers solve problems of high loads in limited space, such as in transmission clutch assemblies, detents and loading fasteners. By combining them in various sequences, Associated Spring can offer a number of load-carrying possibilities.

Belleville washers are used in two broad categories of applications. In one case, they provide very high loads at small deflections such as in metal stamping dies and stacks of belleville washers used in recoil mechanisms and pressure relief valves. The other category utilizes the special nonlinear load deflection characteristics of belleville washers – particularly those with a constant load portion. In these applications, they maintain a constant force regardless of dimensional variations due to wear, temperature changes or tolerances.

Our broad experience with metal stamping enables our precise solutions engineers to offer the exact custom belleville washer to meet your application requirements. Curved, wave, finger and disc spring washers are also available in many materials and sizes. Our plants are third-party certified to AS9100, ISO9001 or TS16949 and ISO 14001 depending on the markets serviced.

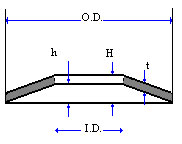

How to Specify:

A blueprint or sketch is the best way to specify your custom Belleville washer. Consultation with Associated Spring engineers early in the design stage will ensure all critical aspects of your spring washer will be met. Associated Spring engineers can develop a print if provided with the space available and part requirements, heights, loads, etc.

Instead of < and > please use “less than” or “greater than”; instead of / use “-” or “;” to separate values